The active development phase of the CASCELLA 3.5mm Superior Clavicle Plate started in March 2019. The idea to develop a superior clavicle plate arose from the belief that there had to be a better solution to treating fractures of the clavicle. Due to the highly variable anatomical properties of the clavicle the anatomical fit of existing plates is often considered suboptimal. Furthermore existing systems often have extensive options, instruments and even different screw diameters. Even though this may in rare cases be useful it is often overcomplicated and of no use. The goal was to design a plate to fit the majority of mid-shaft fractures and offer it in a way that would reduce complexity. The design process consisted of several meetings to understand clinical requirements. Plate curvature design was studied using CT data and statistical shape modelling to analyse anatomical variations of the human clavicle. Cadaver labs were conducted in June 2019 to test first designs and to make some adjustments to plate holes, plate lengths as well as changes and additions to instrumentation were made. The final version with two plates (7 hole and 9 hole) came to fruition by July 2019. The most rewarding feature of the plate design was the ability to adapt a nice fit by simply flipping it 180 degrees! One plate, two sizes, to treat the majority of mid-shaft clavicle fractures — reducing complexity at its best.

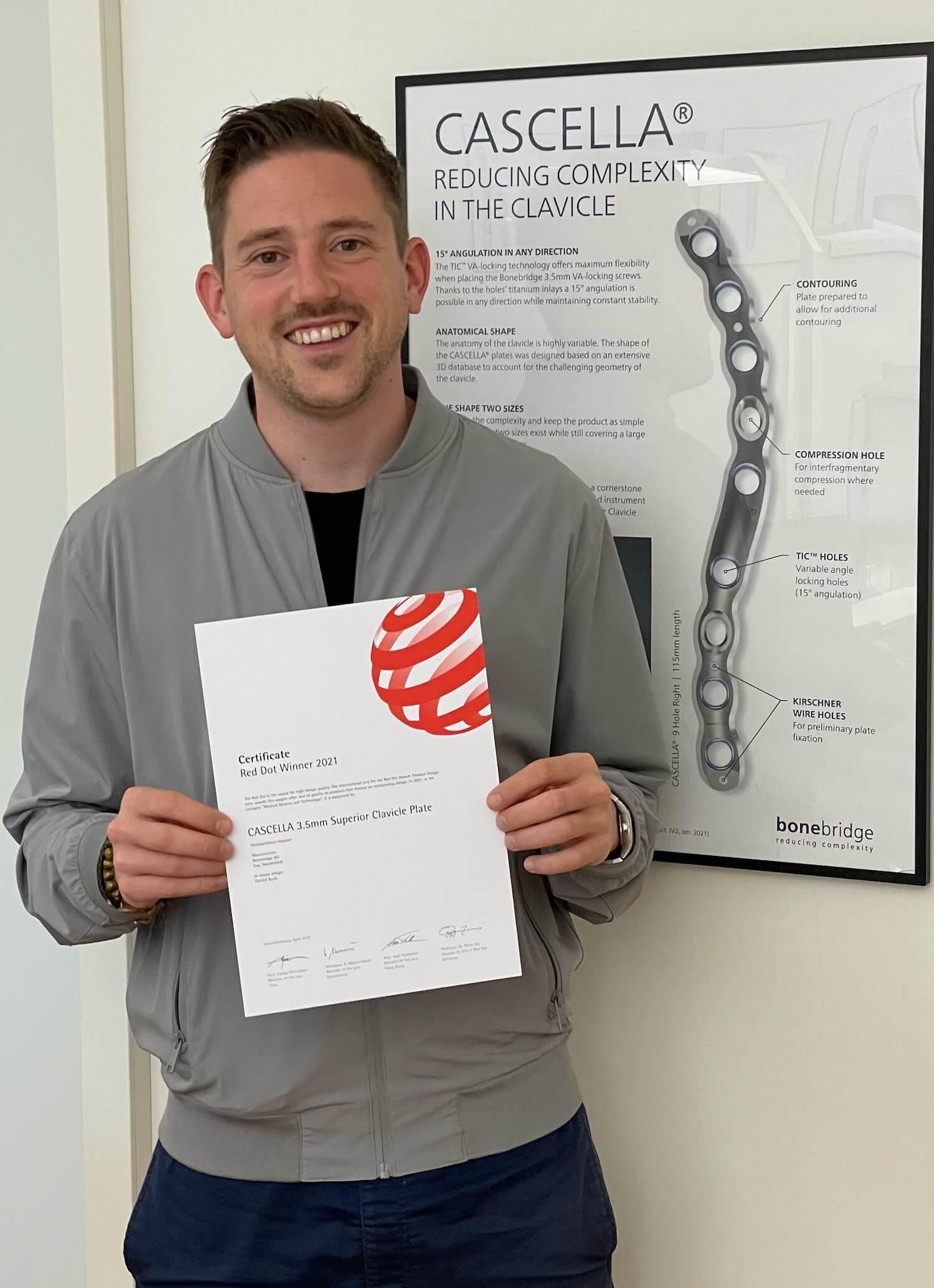

The announcement of the award was made in March 2021 and was an exciting moment for our team. Attainment of this award emphasises the progress being made towards reducing complexity in the field of orthopaedic trauma. We congratulate Patrick Burki and the members of the technical commission who contributed towards this fine achievement!

30.03.2021 / company news

→ Back To All NewsCASCELLA WINS RED DOT AWARD 2021

Exactly two years after the kick-off of the development phase the CASCELLA 3.5mm Superior Clavicle Plate is announced as a winner of the annual Red Dot Award! The Red Dot Award is an international design competition, which stands for belonging to the best in design and business. Excellent designs are selected by competent expert juries in the areas of product design, communication design, and design concepts. The competition takes place once a year and receives submissions from designers from more than 60 countries worldwide. Winners are published in the annual Red Dot Design Yearbook and a presentation is delivered in an exhibition.

Patrick Burki showing the winner certificate of the Red Dot Award.